Scrap Tire Management

<

Tire recycling

Tire recycling or rubber recycling is the process of recycling vehicles' tires that are no longer suitable for use on vehicles due to wear or irreparable damage (such as punctures).

These tires are among the largest and most problematic sources of waste, due to the large volume produced, their durability, and the fact they contain a number of components that are ecologically problematic. It is estimated that 259 million tires are discarded annually (data is for the 1980s and 1990s).

The same characteristics that make waste tires problematic, their cheap availability, bulk, and resilience, also make them attractive targets for recycling. Nonetheless more than half of used tires are simply burned for their fuel value.

Even in advanced countries like Germany, 55% are estimated to be burnt for fuel.Tires are also often recycled for use on basketball courts and new shoe products. However, material recovered from waste tires, known as "crumb", is generally only a cheap "filler" material and is rarely used in high volumes. They are made to be highly durable and weatherproof, which causes mass landfill space to be used up, as tires are non-biodegradable.

Used tires in foreground waiting to be shredded and shredded tires in background.

The tire life cycle can be identified by the following six steps:

1.Product developments and innovations such as improved compounds and camber tire shaping increase tire life, increments of replacement, consumer safety, and reduce tire waste.

2.Proper manufacturing and quality of delivery reduces waste at production.

3.Direct distribution through retailers, reduces inventory time and ensures that the life span and the safety of the products are explained to customers.

4.Consumers' use and maintenance choices like tire rotation affect tire wear and safety of operation.

5.Manufacturers and retailers set policies on return, retread, and replacement to reduce the waste generated from tires and assume responsibility for taking the 'tire to its grave' or to its reincarnation.

6.Recycling tires by developing strategies that combust or process waste into new products, creates viable businesses, and fulfilling public policies.

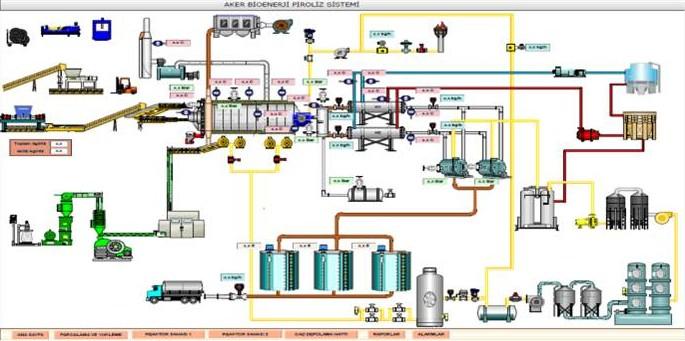

Tire pyrolysis

The pyrolysis method for recycling used tires is a technique which heats whole or shredded tires in a reactor vessel containing an oxygen-free atmosphere. In the reactor the rubber is softened after which the rubber polymers break down into smaller molecules. These smaller molecules eventually vaporize and exit from the reactor. These vapors can be burned directly to produce power or condensed into an oily type liquid, generally used as a fuel. Some molecules are too small to condense. They remain as a gas which can be burned as fuel. The minerals that were part of the tire, about 40% by weight, are removed as solid ashes. When performed properly, the tire pyrolysis process is a clean operation and produces little emissions or waste, howerver, concerns about air pollution due to incomplete combustion as is the case with tire fires have been documented. The properties of the gas, liquid, and solid output are determined by the type of feed-stock used and the process conditions. For instance whole tires contain fibers and steel. Shredded tires have most of the steel and sometimes most of the fiber removed. Processes can be either batch or continuous. The energy required to drive the decomposition of the rubber include using directly fired fuel (like a gas oven), electrical induction (like an electrically heated oven) or by microwaves (like a microwave oven). Sometimes a catalyst is used to accelerate the decomposition. The choice of feed-stock and process can affect the value of the finished products. The historical issue of tire pyrolysis has been the solid mineral stream which accounts for about 40% of the output. The steel can be removed from the solid stream with magnets for recycling. The remaining solid material, often referred to as "char", has had little or no value other than possibly as a low grade carbon fuel. Char is the destroyed remains of the original carbon black used to reinforce and provide abrasion resistance to rubber. The solid stream also includes the minerals used in rubber manufacturing. This high volume component of tire pyrolysis, until recently, has made the economic viability very difficult to achieve. Over the past five years two or three companies have discovered ways to recover the carbon in its original form[citation needed]. These companies have been commercially producing and selling recovered carbon black based products that successfully supplement virgin carbon black in rubber and plastics. Tire-derived products Tires can be reused in many ways, although again, most used tires are burnt for their fuel value. In a 2003 report cited by the U.S. EPA, it is stated that markets ("both recycling and beneficial use") existed for 80.4% of scrap tires, about 233 million tires per year. Assuming 22.5 pounds (10.2 kg) per tire, the 2003 report predicts a total weight of about 2.62 million tonnes (2,580,000 long tons; 2,890,000 short tons) from tires. One stage of tire recycling involves the production of alternate products for sale. New products derived from waste tires generate more economic activity than combustion or other low multiplier production, while reducing waste stream without generating excessive pollution and emissions from recycling operations.

WER HAVE CONTRACTS WITH MOTS COMPETITIVE AND RELIABLE VENDORS AND CAN PROPOSE YOU THE MOTS APPROPRIATE SYSTEM SUITHS YOUR APPLICATION